Differences between flexible and rigid LED panels: applications and benefits

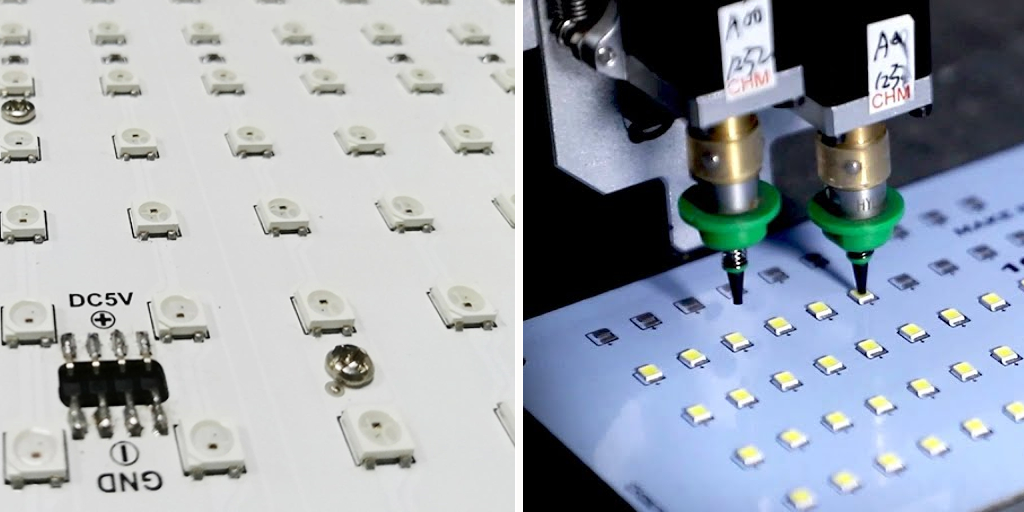

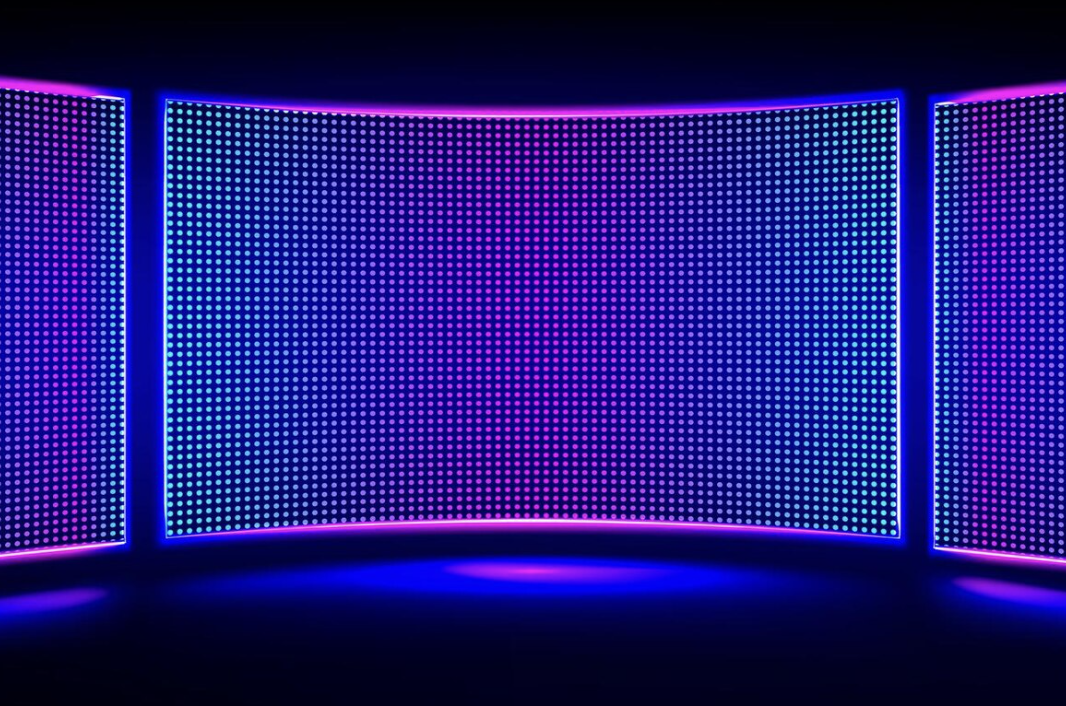

Differences between flexible and rigid LED panels: applications and benefits LED display technology has evolved dramatically over the past decade, offering creative and high-performance solutions for both indoor and outdoor applications. Among the most versatile options available today are flexible Read more